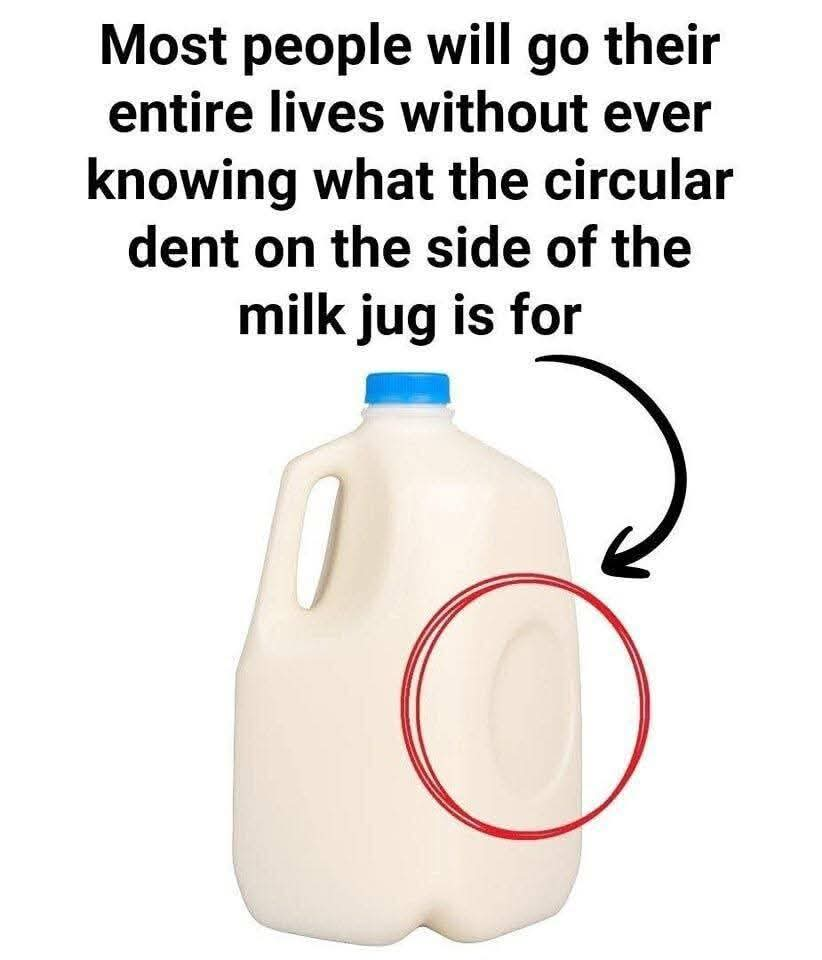

Purpose of the Circular Dent on Milk Jugs

If you have ever picked up a plastic milk jug, you may have noticed a circular dent or indentation on one or more sides of the container. This small design detail often goes unnoticed, yet it serves several important purposes. Far from being a random or purely aesthetic feature, the circular dent plays a crucial role in the strength, safety, efficiency, and usability of milk jugs. Understanding why this dent exists provides insight into packaging engineering, material science, and consumer safety.

This article explores the purpose of the circular dent on milk jugs in detail. We will examine how it contributes to structural stability, pressure control, transportation efficiency, sustainability, and even user experience. By the end, you will see how a simple indentation reflects thoughtful engineering and practical design.

Overview of Milk Jug Design

Plastic milk jugs are typically made from high-density polyethylene, commonly known as HDPE. This material is lightweight, durable, resistant to impact, and safe for food storage. Milk jugs are designed to hold liquid securely, withstand temperature changes, and survive transportation from dairy farms to processing plants, warehouses, grocery stores, and finally to consumers’ homes.

Every aspect of a milk jug’s design serves a function. The handle allows for easy pouring, the cap ensures freshness and prevents spills, and the overall shape allows the jugs to be stacked efficiently. The circular dent is part of this carefully engineered system, designed to improve the jug’s performance under real-world conditions.

Structural Strength and Stability

One of the primary purposes of the circular dent on a milk jug is to increase structural strength. When a container is filled with liquid, it experiences internal pressure. Milk is relatively heavy, and when the jug is lifted, tilted, or stacked, stress is placed on the plastic walls.

The circular dent acts as a reinforcement point. Much like arches in architecture or ribs in construction, the indentation helps distribute stress more evenly across the surface of the jug. This prevents the plastic from bulging outward or collapsing inward under pressure.

Without this dent, the sides of the jug would be flatter and more prone to deformation. Over time, repeated stress could cause cracks, leaks, or complete structural failure. The circular shape is particularly effective because it spreads force in all directions, making the container stronger without requiring thicker plastic.

Pressure Regulation and Temperature Changes

Milk jugs are exposed to changes in temperature throughout their lifecycle. Milk may be stored in cold environments, transported in refrigerated trucks, and later placed in home refrigerators. Temperature changes cause liquids and gases to expand and contract.

The circular dent helps accommodate these pressure changes. When the temperature drops, the liquid contracts slightly, creating a vacuum inside the jug. The dent can flex inward to compensate, preventing the jug from collapsing in an uncontrolled way.

Similarly, when the temperature rises, the liquid expands, increasing internal pressure. The dent can flex outward slightly, reducing the risk of the jug swelling or bursting. This flexibility helps maintain the jug’s shape and integrity across a wide range of conditions.

Impact Resistance and Drop Protection

Milk jugs are often dropped, bumped, or knocked over during handling and use. Whether in a grocery store, during transportation, or at home, accidents happen. The circular dent contributes to the jug’s ability to withstand impact.

When a jug hits the ground or another surface, the dent acts as a shock absorber. It allows the plastic to deform slightly and then return to its original shape, dissipating energy that might otherwise cause cracks or leaks.

This design feature reduces product loss and improves safety. A jug that breaks easily not only wastes milk but also creates slippery surfaces and potential hazards. The dent helps minimize these risks by making the container more resilient.

Efficient Use of Materials

Another important purpose of the circular dent is material efficiency. Packaging manufacturers aim to use as little plastic as possible while still ensuring durability and safety. Thicker plastic increases costs, weight, and environmental impact.

By incorporating a dent into the design, manufacturers can strengthen the jug without adding extra material. The shape itself provides rigidity, allowing the walls to be thinner while maintaining performance.

This approach aligns with sustainability goals. Using less plastic reduces resource consumption, lowers greenhouse gas emissions during production, and decreases the amount of waste generated after the jug is discarded or recycled.

Stacking and Transportation Benefits

Milk jugs must be stacked efficiently during storage and transportation. In warehouses and delivery trucks, thousands of jugs are packed closely together. Structural integrity is critical to prevent crushing and leakage.

The circular dent helps jugs maintain their shape under vertical and horizontal loads. When stacked, the pressure from the weight above is distributed more evenly, reducing the risk of deformation.

This stability allows for safer stacking and more efficient use of space. It also reduces losses due to damaged containers, which benefits both manufacturers and retailers.

Manufacturing Advantages

The dent also plays a role in the manufacturing process itself. Milk jugs are typically produced using a method called blow molding. In this process, molten plastic is shaped by air pressure inside a mold.

The circular dent helps control how the plastic stretches and cools during molding. It ensures more uniform wall thickness and reduces weak points that could form during production.

This leads to more consistent quality across large production runs. Fewer defects mean less waste, lower costs, and a more reliable product for consumers.

Consumer Handling and Usability

From a user’s perspective, the circular dent can also improve handling. The indentation provides a subtle grip point, making it easier to hold and control the jug, especially when it is full and heavy.

For children, elderly individuals, or anyone with limited hand strength, even small design improvements can make a significant difference. The dent helps prevent slipping and improves pouring accuracy.

While this may not be the primary reason for the dent’s existence, it is a valuable secondary benefit that enhances overall usability.

Visual Indicators and Quality Control

In some cases, the dent can serve as a visual indicator of pressure changes or spoilage. If a jug appears excessively bulged or collapsed, it may indicate temperature abuse or compromised seals.

While this is not a precise diagnostic tool, consumers and retailers can use changes in the jug’s shape as a general warning sign. The dent makes such changes more noticeable.

This contributes to food safety by encouraging closer inspection of products that appear abnormal.

Environmental and Recycling Considerations

Milk jugs are among the most commonly recycled plastic containers. The dent does not interfere with the recycling process and may even help by maintaining the jug’s shape during collection and transport.

A well-designed jug is less likely to crack or shatter, reducing contamination and improving recycling efficiency. The dent supports this by enhancing durability without complicating material composition.

This thoughtful design reflects a balance between performance, cost, and environmental responsibility.

Common Misconceptions

There are several misconceptions about the circular dent on milk jugs. Some people believe it is purely decorative or that it indicates the fill level. Others think it is designed to prevent spilling or to measure portions.

In reality, the dent’s primary functions are structural and mechanical. While it may offer minor secondary benefits, its main purpose is to improve strength, flexibility, and reliability.

Understanding this helps dispel myths and highlights the importance of engineering in everyday objects.

Why the Dent Is Circular

The circular shape of the dent is not accidental. Circles are one of the strongest geometric shapes when it comes to distributing stress. This is why they are used in bridges, domes, and pressure vessels.

A circular indentation allows forces to spread evenly around its perimeter, reducing concentrated stress points. This makes the jug more resistant to deformation and damage.

Other shapes would not provide the same balance of strength and flexibility, making the circle the most efficient choice.

Conclusion

The circular dent on milk jugs is a small but significant feature that demonstrates the power of thoughtful design. It enhances structural strength, regulates pressure, improves impact resistance, reduces material usage, and supports efficient manufacturing and transportation.

What may seem like a simple indentation is actually the result of careful engineering and practical problem-solving. It shows how everyday objects are optimized to meet multiple demands, from safety and durability to sustainability and convenience.

Next time you pour a glass of milk, take a moment to notice the jug in your hand. That circular dent is quietly doing its job, ensuring that your milk stays fresh, safe, and easy to handle from the dairy to your table.